Concrete Spacer, Cement Spacer

Rebar Spacer Made of Concrete

A concrete spacer is an essential component in creating the proper concrete cover for rebar. If the correct spacing on rebar is not maintained, it will have a direct impact on the lifespan of the concrete structure, depending on the environmental conditions and the structure’s specifications. To ensure accurate rebar placement, both plastic and concrete spacers are used, each having its own set of advantages and disadvantages. Beton Plast Chemical Company has produced a range of cement and concrete rebar spacers in different sizes and models to meet market demand.

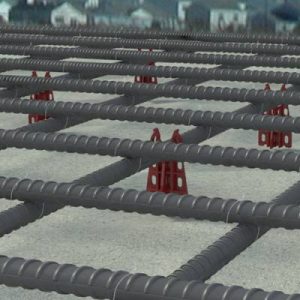

A concrete spacer is a small piece made from concrete, used to create a gap between rebar and formwork in concrete structures. Its primary purpose is to ensure a uniform concrete cover over the rebar to prevent direct contact with air and moisture, thereby protecting the rebar from corrosion.

Applications of Concrete Spacers

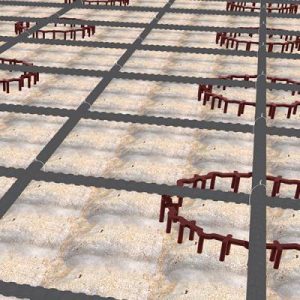

- Ideal for creating a high-density concrete cover over rebar grids.

- Suitable for heavy foundation structures and thick floors where plastic spacers may not be applicable.

- Can be used on both horizontal and vertical surfaces.

- Suitable for bridge decks and tunnel walls.

- Ideal for precast components where visible spacer marks on the surface should be avoided, requiring a clean, exposed finish.

- Suitable for acidic environments and water and sewage rebar networks.

Advantages of Concrete Spacers Over Plastic Spacers

- Can be attached to the rebar framework with wire.

- Does not deform under various temperature fluctuations.

- Provides safer transfer of static loads to the concrete.

- Better bonding with the concrete due to the same material composition.

- Fewer spacers are required per square meter compared to plastic spacers under the same structural conditions.

- Provides better balance under seismic loads during rebar installation and concrete pouring.

- Superior physical and chemical resistance.

- Higher point load capacity than plastic spacers.

- The spacers are invisible after formwork removal.

- More thermally compatible for freeze-thaw cycles than plastic spacers.

- More cost-effective for heavy floor structures.

- More suitable for high-temperature environments as they do not crush like plastic spacers.

- Higher resistance to fire and heat than plastic spacers.

Disadvantages of Concrete Spacers Compared to Plastic Spacers

- Lack of locking prongs to secure rebar in place (Note: Beton Plast Concrete Spacers feature holes for wire attachment to rebar, which requires additional time and cost).

- Installation requires more time compared to plastic spacers.

- Higher transportation and handling costs compared to plastic spacers.

- Requires more storage space than plastic spacers (concrete spacer cartons can be stacked up to 8 layers).

- Increased permeability and corrosion transfer at the spacer contact point, especially in waterproofing applications.

- In vertical applications, wire must be used to secure concrete spacers to the rebar, whereas plastic spacers can easily be installed with locking prongs.

- For lightweight rebar, concrete spacers may provide less stability than plastic ones, requiring the use of wire.

- Higher cost for lightweight structures compared to plastic spacers.

Usage Instructions for Concrete Spacers

- Vertical Surfaces:

After selecting the correct spacer, wire it to the rebar using the holes in the concrete spacer before formwork and concrete pouring. - Horizontal Surfaces:

Choose the appropriate spacer based on the rebar layout and required concrete cover, and place them under the spacers. If structural vibrations are significant during rebar installation or concrete pouring, wire the concrete spacers to the rebar for added stability.

Consumption Rates

The quantity of concrete spacers used depends on the placement and weight of the structure:

- Horizontal Surfaces:

At least 2 concrete spacers per square meter for horizontal surfaces. - Vertical Surfaces:

For vertical surfaces, 2 concrete spacers per meter square are recommended for each side of the wall, depending on formwork type and the pressure from the formwork on the spacer.

Storage and Maintenance

- Shelf life: 5 years in its original packaging.

- Storage conditions: Store away from cold, freezing temperatures, excessive heat, and direct sunlight.

- Optimal storage temperature: Between 10°C and 30°C.

- Stacking: Do not stack more than 8 layers of concrete spacer cartons.

Beton Plast Concrete Spacer Offerings

Beton Plast produces concrete spacers in three models and 11 sizes:

- Hard Cement Spacers (Hard Cement Spacer)

These spacers are suitable for heavy and semi-heavy floors and are available in the following sizes:

| Product | Size (cm) | Product Code | Quantity per Carton |

| Hard Cement Spacer 25 | 2.5 | CE-HARD25 | 1000 |

| Hard Cement Spacer 30 | 3 | CE-HARD30 | 700 |

| Hard Cement Spacer 40 | 4 | CE-HARD40 | 350 |

| Hard Cement Spacer 50 | 5 | CE-HARD50 | 220 |

| Hard Cement Spacer 75 | 5.7 | CE-HARD75 | 100 |

| Hard Cement Spacer 100 | 10 | CE-HARD100 | 70 |

- Multi-Size Cement Spacers

These spacers are designed with different sizes on each side for creating concrete cover in various applications:

| Product | Size (cm) | Product Code | Quantity per Carton |

| Small Multi-Size Spacer | 20/25/30 | MF-MULI-S | 450 |

| Medium Multi-Size Spacer | 30/35/40 | MF-MULI-M | 300 |

| Large Multi-Size Spacer | 35/40/45/50 | MF-MULI-L | 220 |

- Flooring Cement Spacers

These spacers have a flat side for better placement on floors and grooves for different rebar positions:

| Product | Size (cm) | Product Code | Quantity per Carton |

| Small Flooring Spacer | 20/25/40/50 | F-MULTI-S | 200 |

| Large Flooring Spacer | 30/40/50/60 | F-MULTI-L | 90 |

Reviews

There are no reviews yet.