Single Reinforced Joist Spacer

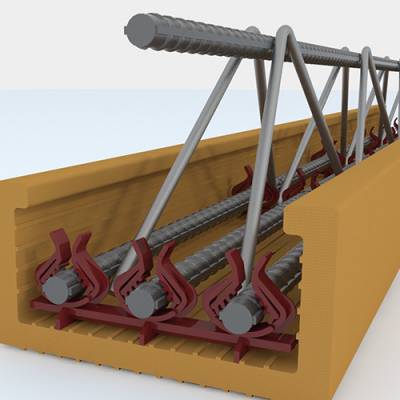

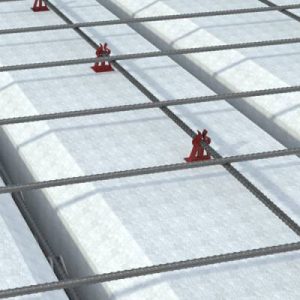

The Single Reinforced Joist Spacer is a widely used product for ensuring proper spacing in precast trusses and placing them inside metal molds for beams or fondoles. This spacer features two locking mechanisms on its sides and an additional central locking feature, specifically designed for securing reinforcement bars within the truss. It is also commonly utilized in modern construction technologies, such as in hollow core slab ceilings (waffle slabs), where trusses and spacers alone can create the necessary spacing between the waffle blocks. The Single Reinforced Joist Spacer can accommodate rebar sizes from 6 mm to 16 mm and can support a point load of up to 50 kg.

For many years, the use of pre-assembled trusses in beam construction has been a standard practice. These trusses are manufactured in factories according to required specifications and then transported to the project or truss fabrication site. During transport, unloading, or loading, the angle of the trusses may change, requiring adjustment before use, which can be a challenging and labor-intensive process. To resolve this, the plastic truss spacer is designed with standard dimensions and the ability to accommodate reinforcing rebar, ensuring that the trusses maintain the correct spacing.

This piece is a plastic tool used to hold the rebar in place and maintain the proper spacing between bars in concrete structures. It is designed to secure the rebar in position and prevent shifting during the concreting process. Proper use of spacers significantly contributes to the durability and strength of concrete structures.

Features of the Single Reinforced Joist Spacer

- Can withstand a point load of up to 50 kg

- Accommodates rebar sizes from 6 mm to 16 mm

- Ensures proper spacing between rebar during concrete pouring

How to Use the Single Reinforced Joist Spacer

- Transporting Trusses:

- During the transfer of precast trusses from the factory to the site, the spacers are installed on the main rebar to prevent deformation during transport.

- Making Beams:

- The spacers are placed inside the metal truss mold at the required distances. Then, the truss is inserted, and the reinforcing rebar is secured within the spacer’s locking mechanism.

- Using in Waffle Slab Molds:

- The plastic truss spacers are placed at regular intervals between the waffle blocks. After this, the truss is inserted into the spacer, and the reinforcing rebar is positioned.

Consumption Rates for the Single Reinforced Joist Spacer

| Application | Consumption Rate |

| Transporting Trusses | Install spacers on the main rebar at intervals of 2 meters. |

| Making Beams | 1 spacer per meter of truss length. |

| Using in Waffle Slab Molds | Place spacers 75 cm apart. |

Important Notes Regarding the Single Reinforced Joist Spacer

- Failing to use this product can result in significant damage due to deformation of trusses, bending of beams, and structural weakness.

- The use of the plastic truss spacer greatly reduces beam construction, transport, and execution time in waffle slab projects.

- The use of these spacers ensures the production of high-quality beams, with the proper details and compliance with standards.

Reviews

There are no reviews yet.