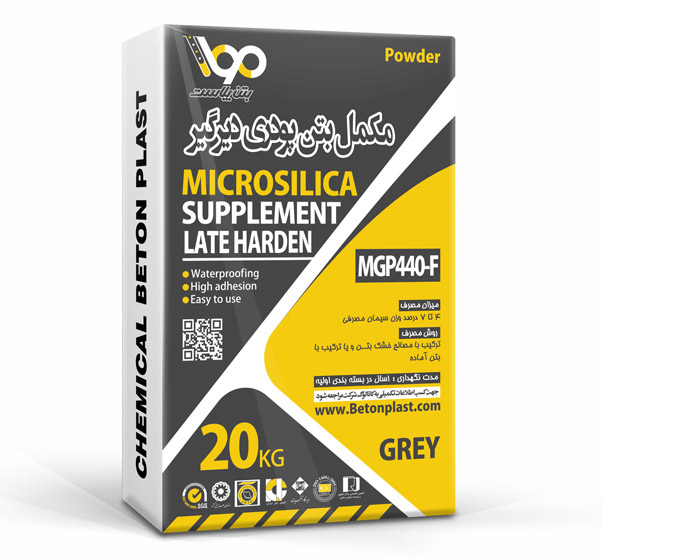

Microsilica Powder Supplement

Retarder

MGP440-L

Powdered Superplasticizer Additive

Waterproofing Retarder

What is Microsilica Powder Retarding Supplement?

The Microsilica Powder Retarding Supplement is a developed product specifically designed for concrete pouring in hot weather conditions. It is formulated using superplasticizers, microsilica powder, waterproofing agents, catalysts, fillers, polypropylene fibers, and retarders to delay the setting time of concrete. It is packaged and supplied in powdered form. This material is added to dry ingredients during the mixing process, followed by the addition of water to the concrete mix. In addition to improving the slump and workability of concrete, the product, due to the presence of superplasticizers, prevents water absorption and reduces permeability in hardened concrete. This property is attributed to the inclusion of nanosilica particles and waterproofing materials in the formulation. Furthermore, the polypropylene fibers in the product enhance the mechanical and abrasion properties of the concrete. The Microsilica Powder Retarder slows the initial setting time of concrete and allows better control of setting time under specific conditions. This product also helps reduce cement consumption by 15 to 20%.

In general, this product is a chemical additive used to delay the setting time of concrete. It is in powdered form and is typically used when an extended workability time for concrete is required. Proper use of this supplement can improve the quality and durability of concrete in various conditions.

Mechanism of Action of Microsilica Powder Retarding Supplement

How does the Microsilica Powder Retarding Supplement work?

When water and cement are mixed, the poly-naphthalene sulfonate molecules in the formulation of the Microsilica Powder Retarder form a charged coating on the cement particles. This causes the cement grains to repel each other, making the concrete more workable. Additionally, naphthalene sulfonates prevent the dissolution of ions such as aluminates, which are the most soluble during the hydration process. The microsilica present in the product, upon mixing with the concrete, reacts with calcium hydroxide (Ca(OH)₂) in the pores of the hardened concrete to form insoluble calcium silicate crystals. This chemical reaction improves the concrete’s density, reduces permeability, and strengthens some of its properties. The retarders in the formulation of the Microsilica Powder Retarder also help control the initial setting time of the concrete.

Properties and Effects of Microsilica Powder Retarding Supplement

What properties and effects does the Microsilica Powder Retarder have on concrete?

- Can replace Type 5 cement with Type 2 cement

- Provides early compressive strength

- Reduces the water-to-cement ratio by approximately 10 to 15%

- Increases bending and tensile strength of concrete

- Improves workability and extended workability time of concrete

- Reduces cement consumption by 15 to 20%

- Increases concrete flowability and slump

- Compatible with all types of Portland cement

- Compatible with all types of Portland cement

- Facilitates pumping and reduces wear on pouring equipment

- Reduces concrete permeability and water absorption

- Prevents the penetration of chloride ions and other harmful ions into the concrete

- Increases compressive strength of concrete by approximately 40 to 60%

- Controls the setting time of concrete and enables concrete production and transport over long distances

Applications of Microsilica Powder Retarding Supplement

What are the main applications of the Microsilica Powder Retarder?

- Suitable for pouring concrete for piers, tanks, treatment plants, pools, bridges, etc.

- Ideal for concrete pouring in tropical climates

- Capable of producing impermeable and waterproof concrete

- Suitable for producing reinforced concrete by eliminating thermal reinforcements

- Suitable for making concrete for all structural elements

- Ideal for making durable and high-strength concrete

- Suitable for concrete pouring in areas affected by harmful chemical ions

- Suitable for concrete pouring in water treatment plants, pools, channels, etc.

Physical and Chemical Properties of Microsilica Powder Retarding Supplement

What are the physical and chemical properties of the Microsilica Powder Retarder?

- Form: Powder

- Color: Dark Grey

- Specific Gravity: 1.43 gr/cm³

- Chloride Ion: None

Standard of Microsilica Powder Retarding Supplement

According to which standards is the Microsilica Powder Retarding Supplement produced?

- ASTM C1202 – BSEN 12390

Consumption Rate of Microsilica Powder Retarding Supplement

What is the standard consumption rate of Microsilica Powder Retarding Supplement?

The required consumption rate of the Microsilica Powder Retarder is determined based on laboratory tests and the environmental conditions and required strengths. However, the typical consumption rate is between 5 and 8% of the cement weight used. It is recommended that the water-to-cement ratio be 0.4 when adding this product to the mix.

Usage Method of Microsilica Powder Retarding Supplement

What is the proper method for using the Microsilica Powder Retarder?

The Microsilica Powder Retarder can be added to the mix in two ways:

- The best method is to add it to the dry ingredients first. After mixing with the dry materials, water is then added, and the mixture is blended.

- Alternatively, the Microsilica Powder Retarder can be added to ready-mix concrete.

Note: For thorough mixing and achieving a uniform, homogeneous mixture, it is recommended to mix for at least 1 minute per cubic meter of concrete.

Safety of Microsilica Powder Retarding Supplement

What safety precautions should be followed when using Microsilica Powder Retarding Supplement?

- If swallowed, immediately seek medical attention.

- If it comes into contact with skin or eyes, wash immediately with plenty of clean water.

- This product is not toxic or harmful to the environment.

- It is recommended to use a mask, gloves, and safety goggles when handling any chemical materials.

Storage of Microsilica Powder Retarding Supplement

What is the correct way to store Microsilica Powder Retarding Supplement?

- Shelf Life: One year in original packaging

- Storage Conditions: Keep away from freezing temperatures, heat, and direct sunlight

- Best Storage Temperature: +10°C to +30°C

Packaging of Microsilica Powder Retarding Supplement

What is the common packaging for Microsilica Powder Retarding Supplement?

- 20 kg Bag

Reviews

There are no reviews yet.