Concrete Paving Mold Model HEXARC X3550

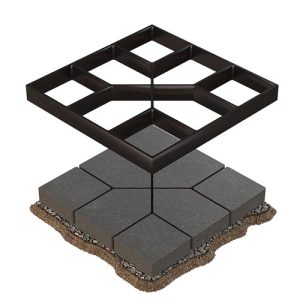

Concrete Paving Mold Model HEXARC X3550 is a unique and specialized tool compared to other molds available worldwide. This mold, with dimensions of 35*50 cm, a height of 4.5 cm, and a blade thickness of 6 mm, is made from durable ABS plastic. It allows for easy and efficient paving of various areas such as villa yards, apartment courtyards, parks, and urban green spaces without requiring any special skills or expertise.

Using a cement paving mold for ground and landscape construction not only simplifies the process but also enables the creation of beautiful designs with colored mortars. The geometric design of this mold consists of irregular arcs, providing an aesthetically appealing appearance. Paving walkways and yards in villa gardens, parks, and green spaces with the HEXARC X3550 plastic cement paving mold is the easiest and most convenient method compared to traditional techniques like mosaic work or concrete pouring. Below, we will explore more advantages of this method.

Key Features of the HEXARC X3550 Paving Mold

- Made from high-quality, durable ABS plastic, offering excellent mechanical resistance to various weather conditions.

- High durability against impacts and physical forces, preventing cracks or breaks.

- The ABS plastic provides excellent resistance to wear caused by contact with mortar or concrete during molding or demolding.

- The mold is designed to prevent mortar from sticking during the casting process.

- No breakage or chipping occurs during concrete pouring or demolding.

- Ability to use various colored mortars in different cells for aesthetic purposes.

- Easy to clean using water and a brush, without needing any special acid cleaners.

- No need for prior subfloor preparation, leveling, or slope adjustment before paving with the HEXARC X3550.

- Can be used on uneven or sloped surfaces without complex procedures.

- Multiple mold types can be used together for varied and beautiful paving patterns.

- For added beauty, grass, plants, or pebbles can be placed in the gaps between cells.

Paving Process with the HEXARC X3550 Mold

The most important factor when paving using the cement paving mold is the physical condition of the mortar to be poured into the molds. The cement content should not be less than 300, with 350 being the recommended standard. The slump of the mortar should be between 4 to 6 to avoid excessive moisture and ensure the mold works effectively. If a higher slump is used, the working cycle will increase, and the curing process may be delayed.

Before positioning the molds, it’s recommended to lubricate them with an appropriate oil or diesel. Ensure the mold is saturated with fresh water to prevent the concrete mix from absorbing too much moisture before curing.

Once the molds are in place, the mortar should be poured into the cells and smoothed. If using multiple colors, smaller trowels may be helpful for precise placement. After filling the molds, lightly tap the surface to help settle and compact the mortar.

Allow the mortar to cure for 2 to 3 hours before removing the molds. When removing, ensure the molds are lifted vertically to avoid damaging the pattern. After demolding, the surface should be cured with water for at least 3 days.

The newly paved surface can be walked on after 24 to 48 hours, and after 7 days, it will be ready for heavy traffic, such as vehicles.

Required Number of HEXARC X3550 Molds for Paving

The number of molds required depends on the area to be paved and the available time. For areas smaller than 50 m², at least 2 molds are recommended. For larger areas, between 4 and 12 molds should be used to increase the speed of execution and allow for adequate initial curing.

Reviews

There are no reviews yet.