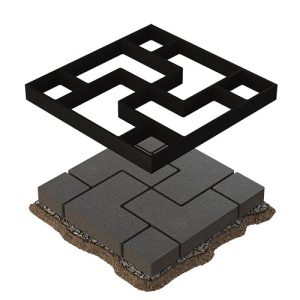

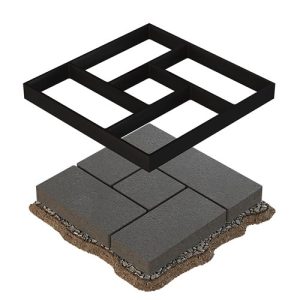

ARCO X100 Concrete Pavement Mold

The ARCO X100 is a circular plastic mold designed for creating round concrete pavements. It is one of the most widely used molds in flooring applications, especially for easy and efficient installation of round concrete pavings. This mold, made of durable ABS plastic, features a 35 cm outer diameter, 4 cm height, and 6 mm thickness of its edges. It is used to construct pavings for various outdoor areas like villas, parks, green spaces, sidewalks, and garden paths.

The ARCO X100 mold can be used easily without any special skills or expertise. The mold is designed to help create beautiful concrete pavings, especially when colored mortars are used. Its circular exterior shape and lack of internal stiffeners make it easy to arrange the molds next to each other to expand the pattern in any direction.

Key Features

- Material and Durability:

The mold is made from high-quality ABS plastic, offering excellent resistance to various weather conditions, impacts, and pressure. The mold’s resistance to abrasion makes it highly durable and able to withstand repeated use, provided proper maintenance. - Design and Versatility:

The mold’s design allows for simple, repeatable expansion in any direction, creating an attractive pavement pattern with regular or irregular spacing. The ability to use colored cement or mortar in the mold makes the process more versatile and the end result more aesthetically pleasing. - No Need for Special Surface Preparation:

The ARCO X100 mold doesn’t require surface leveling or preparation, which makes it an excellent choice for uneven and sloped surfaces. It can also be used for creating decorative cement walkways or patterned concrete on various terrains. - Easy Maintenance:

The mold can be cleaned quickly with water and a brush, without the need for any special acidic detergents. Its low maintenance cost adds to its efficiency.

Advantages of ARCO X100 Mold

- High Impact and Wear Resistance:

The ARCO X100 mold is made from tough ABS plastic, ensuring it resists impact and wear over time. It won’t easily crack or break, even under pressure. - Ease of Use and Cost-Effectiveness:

The mold is very easy to use for creating pavement designs without requiring special training. It’s a cost-effective alternative to traditional methods like mosaic installation, concrete pouring, or using pre-made concrete tiles. - Improved Aesthetics:

Using colored mortars in the mold allows for beautiful and vibrant pavement designs. The pattern can be customized with different colored mortars for added visual appeal. - Increased Durability:

The mold’s resistance to adhesion from cement and mortar ensures that the mold can be reused multiple times without degradation, making it a long-lasting tool for concrete pavement projects. - Maintenance and Storage:

The ARCO X100 mold can be easily cleaned and stored for future use, reducing waste and increasing its lifespan.

How to Use the ARCO X100 Mold for Paving

- Preparation of the Surface:

There is no need for extensive ground preparation before using the ARCO X100 mold. If working on an uneven surface, the mold can still be used effectively. - Mixing the Mortar or Concrete:

The cement or concrete mix should have a slump of 4-6 for best results. Ensure the mix is neither too runny nor too thick to avoid poor finishing quality. - Mold Application:

Apply the mixed mortar into the mold’s cells using a trowel, making sure to evenly fill each section. You can use different colored mortars in each section for a multi-colored design. Tap the mold lightly to help compact the mortar for a more solid and durable surface. - Curing the Concrete:

After the mortar sets, allow it to cure for 2-3 hours before removing the mold. Ensure the mold is removed carefully to prevent damaging the created pattern. Once removed, let the surface cure for at least 3 days by spraying with water. - Final Finish:

After curing, the paved surface can be walked on after 24-48 hours, and it will be fully ready for heavy loads such as vehicular traffic within 7 days.

Calculating the Number of Molds Required

- For small areas, it is recommended to use at least 2-4 molds, whereas larger areas may require up to 16 molds or more to speed up the process and ensure an even, high-quality result.

Conclusion

The ARCO X100 plastic mold is an excellent tool for creating beautiful and durable concrete pavements in outdoor areas. Its easy-to-use design, low maintenance, and cost-effectiveness make it a great choice for both small-scale residential projects and large-scale urban or industrial applications.

Reviews

There are no reviews yet.