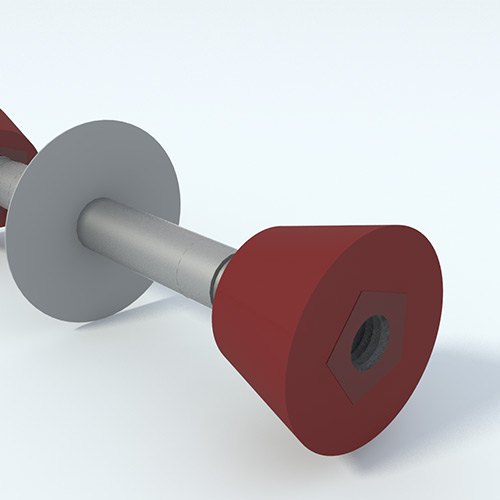

Plastic Conical Nut

Plastic Nut Conical

A plastic component used in the concrete formwork process.

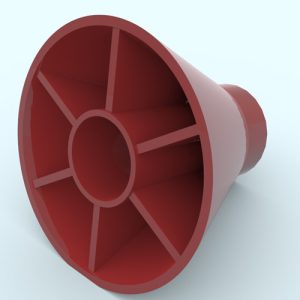

The plastic conical nut is utilized during the concrete formwork stages. These conical nuts have a tapered shape that is used in concrete formwork systems to secure lateral pressure forces of the concrete.

The use of bolts, nuts, washers, and other anchoring elements in concrete formwork systems is essential for containing lateral pressure. If the formwork is not properly secured, the hydrostatic pressure from the poured concrete can cause the formwork to open, resulting in catastrophic consequences for both the concrete pouring and the structure. Bolt passage areas in concrete structures, such as in pools, tanks, and generally water-related structures, are very important because of the need for waterproofing and the problem of permeability. After the process is completed, these structures must be secured against water infiltration. While filling the bolt hole with waterproofing mortar is possible, it is time-consuming, economically inefficient, and not a foolproof method for reducing permeability.

To seal bolts in walls that require waterproofing, intermediary components can be used. These intermediary components, called “middle bolts,” come in various designs. One type of waterproofing middle bolt consists of a waterproof sheet (waterproof curtain) and a threaded rod at both ends. To maintain the distance between the metallic middle bolt and the surface of the concrete form, a plastic component with a metallic nut placed inside is used, with the threaded rod from the metallic middle bolt connecting and tightening the system.

Overall, this plastic nut is an efficient component used in concrete formwork systems and is made from compressed polyethylene. It is widely utilized in applications requiring secure and stable connections.

This product is an industrial component typically used in various connections and structures. The conical shape of the component allows the nuts to be securely fastened in place, preventing any unwanted movement. This crucial and practical part, with its unique shape and material, has a wide range of uses.

How to Use the Plastic Conical Nut

In the first stage, the rebar structure is woven, and one side of the wall formwork is constructed. In the next stage, the external bolt enters the formwork hole and is fastened to the plastic conical nut. Then, the threaded rod of the metallic middle bolt is attached to the other side of the plastic conical nut. Another plastic conical nut is placed on the other side of the metallic middle bolt, and finally, after securing the external bolt, the other side of the wall formwork is assembled, and the formwork is secured by tightening the nuts, washers, and other anchors. After pouring the concrete and removing the formwork, the visible plastic conical nut will be removed from the concrete, and the resulting hole will be filled with appropriate waterproof mortar.

Consumption Rate of the Plastic Conical Nut

The required number of plastic conical nuts is twice the number of holes in the wall and formwork where the bolts pass through. In other words, for every middle bolt in the wall formwork system, two plastic conical nuts are needed.

Important Notes about the Plastic Conical Nut

- Failure to use the plastic conical nut will allow corrosion to penetrate from the steel into the rebar network.

- Ensure that after the concrete is poured and the formwork is removed, the plastic conical nut is taken out from the surface of the concrete.

- After formwork removal, be sure to fill the remaining hole with waterproof mortar to prevent harmful agents from penetrating the rebar network and causing corrosion.

Reviews

There are no reviews yet.