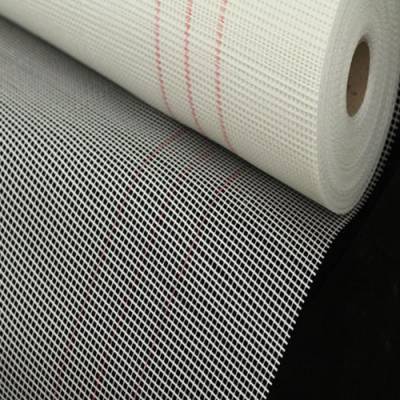

Fiber Glass Mesh

FG40

Fiberglass Mesh for Concrete

Reinforcing Surface Mortars

Fiberglass mesh is widely used for surface coatings such as insulation, waterproofing, and repairs with various materials applied in different structural components. These materials are typically applied in two or more layers on surfaces and have a specific lifespan. Over time, they can weaken or deteriorate due to environmental factors. Modern technologies allow for the reinforcement of surface insulations, similar to reinforced concrete, enhancing durability and quality. One such modern product for reinforcing surface coatings is fiberglass mesh. It is a composite mesh made from glass fibers combined with polymer base materials, which serve as stabilizers for the polymer materials. The fiberglass mesh reinforces various insulation and waterproof coatings on surfaces such as swimming pools, reservoirs, concrete surfaces, and roofs. Due to the unique design of the fiberglass mesh, it has a high resistance to hydraulic pressure, making it highly suitable for strengthening and stabilizing structures. The lifespan of fiberglass mesh corresponds to the lifespan of the materials it reinforces, and it can be used at all stages of construction. Fiberglass mesh significantly increases tensile, compressive, and bending strengths, and it can easily cover hard-to-reach corners and edges. Due to this special property, it plays a crucial role in the application of waterproofing materials in areas such as the junctions of the walls and floor of a pool.

In general, fiberglass mesh is a type of glass fiber used in a woven form. Its application across various industries requires properties such as mechanical strength, heat resistance, electrical insulation, and other favorable physical and chemical characteristics. This mesh is commonly used as a reinforcement for building frameworks.

Mechanism of Action of Fiberglass Mesh

What effect does fiberglass mesh have on surface coatings?

Fiberglass mesh acts like a grid with square openings, placed between two layers of surface coatings and mortar, providing reinforcement to the surface layer. Fiberglass mesh is produced in various weights and grid sizes, with each type being suitable for different applications.

Properties and Effects of Fiberglass Mesh

What features does fiberglass mesh offer?

- High strength at various temperatures

- Long lifespan, equal to the lifespan of the reinforced structure

- Low thermal expansion and high thermal conductivity

- Maintains desired mechanical strength in moist environments

- Strong electrical insulation with excellent tensile strength and elasticity

- High chemical durability against acids and bases

- Excellent heat resistance

- Non-flammable due to its inorganic nature

- Resistant to fungi, bacteria, and pests due to its inability to absorb moisture (though it may swell without stretching)

Applications of Fiberglass Mesh

Where is fiberglass mesh used?

- Compatible with various resins to reinforce construction surfaces and floors

- Strengthens the natural texture of stone in stone factories

- Suitable for stabilizing construction materials

- Ideal for reinforcing insulation and bitumen materials

- Can replace metal mesh in warehouse ceilings

- Can make structures earthquake-resistant with bitumen materials

- Suitable for repairing concrete surfaces, cracks, and joints

- Increases tensile strength and stability of construction materials

- Suitable for reinforcing intersections of walls and joints

- Ideal for strengthening concrete, gypsum, and prefabricated ceilings and walls

- Forms a uniform texture in walls and floors to prevent cracking

- Allows the use of thinner plaster and mortar layers on walls and floors, enhancing bonding

- Can be used on various surfaces before plastering and concreting

- Suitable for strengthening marble facades, particularly when installing stone, tiles, and ceramics

- Ideal for repairing cracks and preventing their recurrence

Physical and Chemical Properties of Fiberglass Mesh

- Form: Mesh

- Color: White

- State: Solid

- Weight per square meter: 45, 60, and 75 grams

- Mesh Size: 4×4

Consumption of Fiberglass Mesh

How much fiberglass mesh is required?

The amount of fiberglass mesh used depends on the area that needs coverage.

Method of Using Fiberglass Mesh

How is fiberglass mesh used?

- As a Middle Layer: First, apply the first layer of insulation, and before it fully hardens (when it is still tacky to the surface), place the mesh on the surface and then apply the second layer.

- As a Bottom Layer: Place the fiberglass mesh on the surface and apply the desired insulation over it.

Safety of Fiberglass Mesh

Is fiberglass mesh dangerous?

Fiberglass mesh is not toxic or hazardous to humans or the environment. However, when using it, it is recommended to wear goggles and gloves.

Storage Conditions for Fiberglass Mesh

How should fiberglass mesh be stored?

- Duration: 2 years in the original packaging

- Conditions: Keep away from direct sunlight and moisture

- Temperature: Between +10°C to +30°C

Packaging of Fiberglass Mesh

Available in rolls of 50, 200, and 250 square meters.

Reviews

There are no reviews yet.