Flat Base Waterstop

PVC Waterstop

Implementing large-scale concrete floor structures as a single, continuous pour is not feasible, as it would lead to structural weaknesses in the concrete. Typically, large surface concrete pours are executed in smaller, formwork-defined sections. This method of execution results in construction joints within the concrete structure, which pose a significant weakness, especially for structures exposed to water, liquids, and negative water pressure. These joints create a pathway for liquid infiltration from the outside into the structure during its service life.

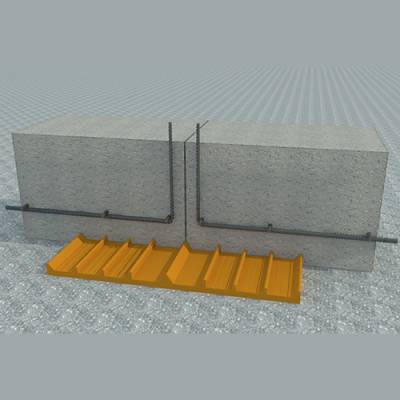

To address this issue, specialized waterstops have been designed and manufactured specifically for construction joints in concrete floor structures. In concrete floors with construction joints, a flat base waterstop or embedded flat waterstop is used. The flat base waterstop is produced with one side textured and the other side smooth. Compared to wall-type waterstops, it features wider and taller ribs. Flat base waterstops have prominent primary ribs, with the number of ribs varying according to the width of the waterstop. Grooves between the ribs prevent water infiltration at the interface between the waterstop and concrete. Additionally, flat base waterstops are typically used for sealing construction joints in floors, with the smooth edge placed flat on the structure’s base while the ribs face upward. They are generally manufactured in widths of 24 cm and 30 cm, with thicknesses ranging from 3 mm to 5 mm.

Properties of Flat Base Waterstop

- Higher tensile strength than standard requirements

- High flexibility in both longitudinal and transverse directions

- Resistant to acids and alkaline substances

- Service life equal to the lifespan of the structure

Applications of Flat Base Waterstop

- Prevents water passage through construction and expansion joints

- Seals joints in concrete structures exposed to water and liquids

- Provides waterproofing for dams, canals, and concrete pipes

- Suitable for waterproofing hydraulic structures

- Capable of sealing swimming pools and artificial lakes

Installation Method of Flat Base Waterstop

Place the waterstop at the designated joint location where concrete pouring is planned to stop, ensuring that half of the waterstop width is embedded in the first concrete pour and the other half is embedded in the second pour. Pour the concrete carefully to prevent displacement of the waterstop from its position.

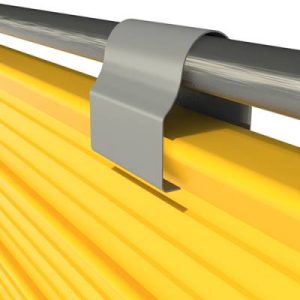

For perforated waterstops, the same installation method applies, with the difference being that the waterstop’s perforation must precisely align with the predetermined expansion joint location. To fix and stabilize the waterstop within the structure, use specially designed clamps for this purpose.

Connecting the Ends of Flat Base Waterstop

The connection of two waterstop ends can be achieved using two methods:

- By Heat Welding: Using a soldering iron, heat both ends of the waterstop until they reach a molten state. Then, press them together until a seamless connection is formed, which solidifies into a uniform joint upon cooling.

- By Industrial Adhesives: Soft PVC-compatible industrial adhesives can be used to bond the two ends of the waterstop. Approximately 30 cm of each end is overlapped, and adhesive is applied between them. The connection is then pressed under pressure to ensure complete adhesion.

Storage Conditions of Flat Base Waterstop

To maintain the properties of waterstops, they should be stored in their original packaging and covered with protective tarpaulins to shield them from sunlight, oxygen, and ozone exposure. Under these conditions, the declared mechanical properties remain stable for up to 12 months.

Reviews

There are no reviews yet.