Hydrophilic Swelling Waterstop

Hydrophilic WaterSeal – WHL 205

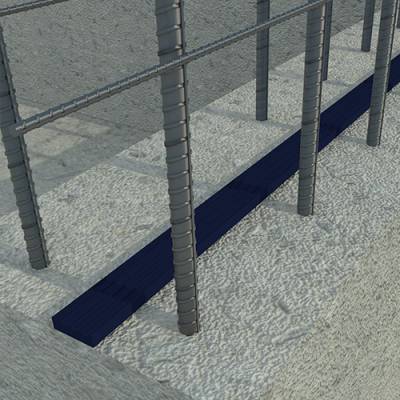

Hydrophilic waterstops are made from unvulcanized thermoplastic elastomer (TPE) and are highly effective for sealing construction joints. These waterstops expand upon contact with water, reaching approximately 400% of their original volume after 14 days. The swelling process begins within 6 hours of water exposure.

A key point about hydrophilic waterstops is that they should only be used in construction joints and must not be applied in expansion joints. These waterstops are composed of water-absorbing materials, preventing water infiltration into critical structural areas.

Key Features and Benefits

- Provides waterproofing for concrete structures under water pressure up to 6 bar

- Reduces installation errors compared to PVC waterstops

- Offers reversible swelling in the presence of water

- Maintains structural integrity even at high temperatures

- Non-toxic and safe for use in potable water reservoirs

- Easy installation with minimal risk of error

- Cost-effective waterproofing solution

Applications

- Suitable for construction joints exposed to groundwater, surface water, and humidity

- Can be applied in both horizontal and vertical construction joints

Physical & Chemical Properties

| Property | Value |

| Color | Black |

| Swelling Ratio (14 days) | 150% (minimum) |

| Specific Gravity (at 25°C) | 1.35 g/cm³ |

| Elongation at Break | 300% |

| Cold Resistance Test | No abnormal deformation |

| Size | 20 × 30 mm |

| Water Permeability | 45 mm |

| Hydrostatic Resistance | ≥ 70 m |

| Standard Compliance | ASTM D 217 |

Installation Instructions

- Surface Preparation: Ensure all surfaces are clean, dry, and free of loose particles before installation.

- Placement: Position the waterstop manually into the designated groove in the concrete.

- Clearance: Maintain at least 8 cm distance from the waterstop edges.

- Fixation: Secure the waterstop using adhesive, nails, or screws at 25 cm intervals to prevent displacement.

- Overlapping Ends: Overlap roll ends by at least 3 cm to ensure a continuous seal.

- Additional Waterproofing: Apply a cementitious crystalline waterproofing layer to the substrate before installing the waterstop.

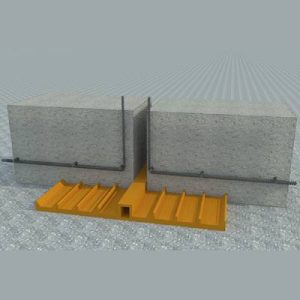

- Joint Configurations:

- Corner Joints: Cut the waterstop at a 45° angle and overlap the vertical strip over the horizontal strip.

- Cross (+) Joints: Cut four sections at 45° angles, align them to form a cross, and secure with nails or screws.

- T-Joints: Place two waterstop strips perpendicular to each other and fix them securely.

- Concrete Pouring: Complete the concrete pour shortly after installation to maintain effectiveness.

Storage & Shelf Life

- Can be stored for up to 2 years in original packaging under normal environmental conditions.

- Protect from direct sunlight and excessive moisture.

Packaging

- 15-meter rolls

Reviews

There are no reviews yet.