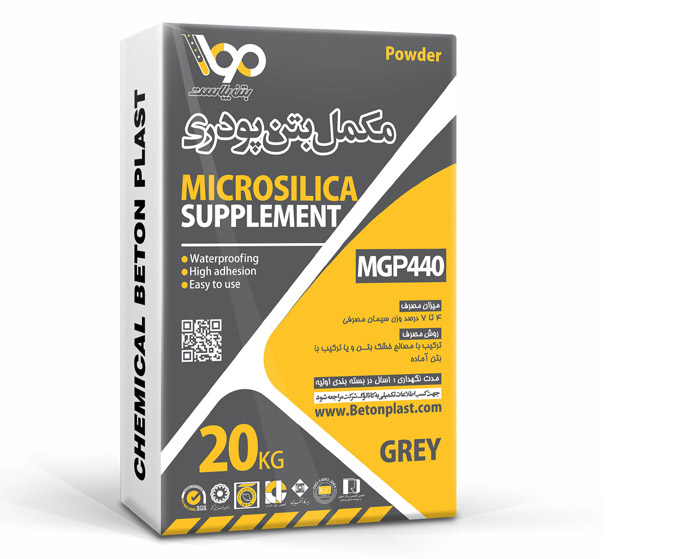

Microsilica Powder Supplement – MGP440

Powdered Plasticizer Additive

Waterproofing Agent – Reduces Concrete Permeability

What is Microsilica Powder Supplement?

Microsilica Powder Supplement is a developed product consisting of concrete plasticizers based on poly-naphthalene, microsilica powder, water repellents, catalysts, filler materials, and polypropylene fibers, available in powder form. During the concrete production process, it is added to the dry materials, and then water is mixed in. This material, in addition to increasing the slump during concrete mixing and improving workability, prevents water absorption due to the inclusion of plasticizers in its formulation, thereby reducing the permeability of hardened concrete. This property is due to the presence of nanosilica particles and water-repellent materials in the formulation. Additionally, the polypropylene fibers in this product enhance the mechanical and abrasive properties of the concrete. Furthermore, its use leads to a reduction of 15 to 20 percent in the cement content.

In general, the provided product is a chemical additive that is added to concrete in powder form to enhance its performance. This additive helps improve various properties such as increasing strength, reducing permeability, improving workability and setting time, and enhancing the durability of concrete.

Mechanism of Action of Microsilica Powder Supplement

How does the Microsilica Powder Supplement affect concrete performance?

When water and cement are mixed, the poly-naphthalene sulfonate molecules in the Microsilica Powder Supplement form a charged layer around the cement particles. This causes repulsion between the cement particles in the concrete mixture, thus making the concrete more fluid. Additionally, the naphthalene sulfonate prevents the dissolution of ions such as aluminates, which have the highest solubility during the hydration process. Moreover, the microsilica in the supplement, after being added to the concrete mixture, reacts with the free calcium hydroxide (Ca(OH)2) in the micropores and microscopic holes of the concrete, producing insoluble calcium silicate crystals. This interaction leads to increased concrete density, reduced permeability, and enhanced certain properties.

Properties and Effects of Microsilica Powder Supplement

What properties and effects does the Microsilica Powder Supplement have on concrete quality?

- Reduces the water-to-cement ratio by approximately 10 to 15%

- Increases flexural and tensile strength

- Enhances workability of the concrete

- Compatible with all types of Portland cement

- Increases the slump and fluidity of the concrete

- Provides early compressive strength

- Increases compressive strength by 40 to 60%

- Reduces permeability and prevents water absorption

- Allows substitution of Type 2 cement for Type 5 cement

- Prevents the penetration of chloride ions and other harmful ions into concrete

- Facilitates easier pumping and reduces wear on concrete pumping equipment

- Reduces cement consumption by 15 to 20%

Applications of Microsilica Powder Supplement

Where can the Microsilica Powder Supplement be used?

- Ideal for concrete used in wastewater treatment plants, swimming pools, canals, etc.

- Suitable for producing durable and stable concrete

- Used for making impermeable and waterproof concrete

- Used for producing reinforced concrete by eliminating thermal reinforcement

- Suitable for concrete in piers, bridges, tanks, silos, etc.

- Can be used in areas exposed to destructive chemical ions

- Useful for making all structural concrete elements

Physical and Chemical Properties of Microsilica Powder Supplement

What are the physical and chemical properties of the Microsilica Powder Supplement?

- State: Powder

- Color: Gray

- Specific Gravity: 2 gr/cm³

- Chloride Ion: None

Standards for Microsilica Powder Supplement

Which international standards is the Microsilica Powder Supplement tested against?

- ASTM C1202 – BSEN 12390

Recommended Consumption of Microsilica Powder Supplement

How much Microsilica Powder Supplement should be used?

The correct dosage of the Microsilica Powder Supplement is determined through precise laboratory testing, taking into account environmental conditions and the required strength. Typically, the recommended consumption is 5 to 8% of the cement weight. It is recommended that the water-to-cement ratio be considered 0.4 when adding the supplement.

Application Method for Microsilica Powder Supplement

How should Microsilica Powder Supplement be applied?

There are two main methods for adding the Microsilica Powder Supplement to the mix:

- The best method is to add it to the dry materials first, mix thoroughly, and then add the mixing water.

Note: To achieve a uniform mixture, it is recommended to mix for at least 1 minute per cubic meter of concrete.

- It can also be added to pre-mixed concrete.

Safety Considerations for Microsilica Powder Supplement

What safety precautions should be followed when using Microsilica Powder Supplement?

- It is recommended to use masks, gloves, and safety glasses when working with any chemical materials.

- The supplement is not classified as toxic or environmentally hazardous.

- If swallowed, seek medical attention immediately.

- In case of contact with skin or eyes, wash thoroughly with plenty of water.

Storage Conditions for Microsilica Powder Supplement

How should Microsilica Powder Supplement be stored?

- Shelf Life: 1 year in its original packaging.

- Storage Conditions: Keep away from cold, freezing conditions, excessive heat, and prolonged direct sunlight.

- Optimal Storage Temperature: 10°C to 30°C.

Packaging of Microsilica Powder Supplement

What is the common packaging for Microsilica Powder Supplement?

- Packaging: 20 kg bags

Reviews

There are no reviews yet.