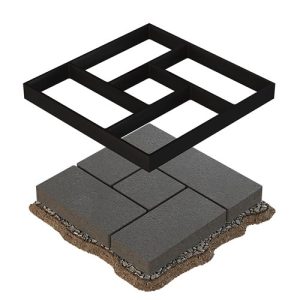

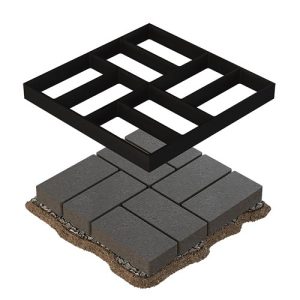

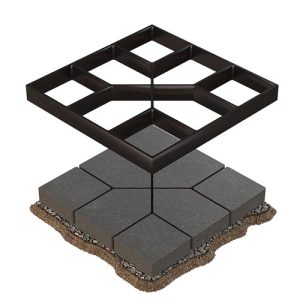

MOLD X110 Concrete Paving Mold

The MOLD X110 concrete paving mold is a beautiful and practical design inspired by the traditional Tabari pattern found in concrete pavements. It consists of 9 identical cells, and with each application of mortar, it creates 9 pieces of paving tiles arranged like a puzzle. This mold, with dimensions of 40×40 cm, a height of 4 cm, and blade thickness of 6 mm, is made from durable ABS plastic. It allows for easy installation of pavements for various areas such as villas, homes, parks, urban green spaces, gardens, and more, without requiring specialized skills.

The unique design of this mold, with an external curved shape and inward and outward arcs, allows the tiles to be arranged in different directions, creating consistent geometric patterns. This mold provides an easy and cost-effective solution for paving paths and areas around homes, villas, gardens, and green spaces, compared to other traditional methods like mosaic installation, concrete pouring, or using pre-made concrete tiles.

Special Features of the MOLD X110 Concrete Paving Mold

- High Durability: Made from high-quality, dense ABS plastic, this mold offers excellent resistance to various weather conditions and temperature changes.

- High Repetition Rate: The mold can be used repeatedly, making it a long-term tool for contractors if properly maintained.

- Impact Resistance: It is highly resistant to impacts and pressure, and will not easily crack or break.

- Wear Resistance: Thanks to the use of ABS plastic, the mold offers excellent wear resistance against contact with mortar and concrete.

- Non-Stick Surface: The mold ensures that the mortar or concrete does not stick to it, making the removal process hassle-free.

- Easy Cleaning: The mold can be easily cleaned with water and a brush, without the need for any acidic cleaning agents.

- No Need for Sub-Base Preparation: The mold allows for paving on uneven or sloped surfaces without the need for additional surface preparation.

- Aesthetic Flexibility: You can use different colored mortars in each cell of the mold to create a vibrant and attractive design.

- Landscaping Potential: You can fill the gaps between the paving tiles with grass, moss, or pebbles to enhance the visual appeal of the paved area.

How to Use the MOLD X110 Concrete Paving Mold

- Prepare the Mortar: The cement mix should have a consistency suitable for pouring into the mold. The recommended mix ratio is around 350, ensuring proper bonding and durability.

- Mold Preparation: It is suggested to lubricate the mold with oil or diesel before use to make the removal process easier.

- Pour the Mortar: Fill the cells of the mold with mortar using a trowel, ensuring an even surface.

- Vibration: After filling the cells, tap the surface gently to compact the mortar and remove any air pockets.

- Initial Curing: Let the mortar sit in the mold for 2 to 3 hours, depending on the weather, to allow initial curing.

- Mold Removal: Carefully remove the mold in a vertical direction to avoid damaging the newly formed concrete.

- Final Curing: Keep the surface moist for at least 3 days after the mold is removed to ensure proper curing.

- Drying: After the initial curing period, the surface can be walked on within 24 to 48 hours and can bear vehicle traffic after 7 days.

Number of Molds Needed

The number of molds required depends on the size of the area to be paved and the available time. Using more molds will speed up the process and provide more time for the mortar to set properly. For small areas, it is recommended to use at least 2 molds, while for larger spaces, 16 or more molds may be required to increase the efficiency of the paving process.

This mold is a cost-effective, efficient, and aesthetically pleasing solution for a variety of paving and landscaping projects.

Reviews

There are no reviews yet.