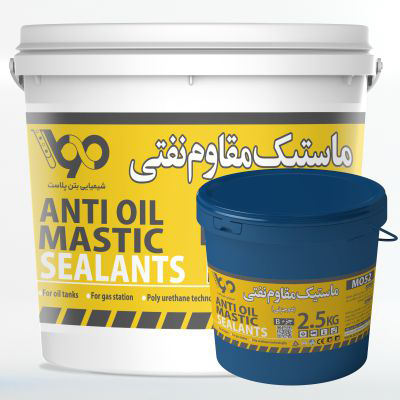

Petroleum-resistant Mastic Sealant

Anti Oil Mastic

M052

Sealing and coating of areas exposed to petroleum-based substances

Solvent and petroleum resistant

What is Petroleum-resistant Mastic Sealant?

Petroleum-resistant mastic sealant is essential for the application of expansion joints in large and extensive floors, and the concrete should be poured in smaller sections using formwork. This method increases the lifespan and durability of the surface, as dividing the area into smaller sections allows it to better resist stresses and external forces. Under normal conditions, standard sealants such as polyurethane mastic, hot-applied mastic, or cold-applied mastic are typically used. However, when the surface is exposed to petroleum and solvent substances, conventional sealants are not suitable. A mastic should be used that has sufficient durability against petroleum substances and will not degrade or empty when in contact with these materials. For this purpose, a specialized sealant known as Petroleum-resistant Mastic Sealant or anti-solvent mastic has been developed and produced. Petroleum-resistant mastic is a two-component filler highly resistant to petroleum solvents, created by blending bitumen and rubber compounds. Many floors and areas exposed to petroleum-based substances and solvents, such as gas station floors, airplane hangars, maintenance garages, fuel storage warehouses, etc., must be sealed with anti-solvent mastic to prevent petroleum and solvents from degrading the mastic and causing the joints to empty. Additionally, this product has excellent resistance to various environmental conditions.

This product, or anti-solvent mastic, is a filler and sealant formulated and manufactured to protect surfaces from petroleum and solvents. It is made from components such as bitumen and rubber, providing high resistance against petroleum solvents, making it ideal for use on surfaces exposed to these materials.

Mechanism of Action of Petroleum-resistant Mastic Sealant

How does the petroleum-resistant mastic sealant work?

The petroleum-resistant mastic sealant consists of two components: resin and powder. When mixed together, they create an exceptional bonding seal that forms a strong connection with the edges of the joint and underlying surfaces. Once fully cured, the mastic becomes a rubbery solid with high elasticity. This elasticity helps the sealed surfaces resist deformation, slipping, and external forces.

Properties and Effects of Petroleum-resistant Mastic Sealant

What are the properties and effects of petroleum-resistant mastic sealant?

- Excellent adhesion to the substrate without the need for a primer

- Extremely durable against oils, petroleum, gasoline, etc.

- High resistance to various weather conditions

- Excellent adhesion to non-concrete surfaces like asphalt, metal, wood, and glass

- Can be applied hot

- Resistant to aircraft fuel

- Excellent resistance across various temperature ranges

- Suitable for expansion joints and junctures with elastic properties

- Suitable for use in tropical climates

- Strong adhesion to concrete surfaces

Applications of Petroleum-resistant Mastic Sealant

What are the applications of petroleum-resistant mastic sealant?

- Suitable for sealing gas station floors and airplane hangars

- Ideal for sealing floors in repair shops and garages

- Suitable for filling concrete joints on airport runways and their surrounding areas

- Ideal for sealing high-traffic parking lots, such as public parking areas

- Suitable for sealing floors in fuel and solvent storage warehouses

- Suitable for sealing floors in factories producing petroleum derivatives

- Used for sealing concrete floors in refinery areas

Physical and Chemical Properties of Petroleum-resistant Mastic Sealant

What are the physical and chemical properties of petroleum-resistant mastic sealant?

| Title | Feature |

| State | Solid elastic component A + viscous liquid component B |

| Color | Black |

| Specific Gravity | 1.35 ± 0.02 gr/cm³ |

| Melting Point | 160°C |

Which Standards Does Petroleum-resistant Mastic Sealant Conform to?

It complies with ASTM D2499 standard.

Consumption Rate of Petroleum-resistant Mastic Sealant

The consumption of anti-solvent mastic varies based on the length, width, and depth of the joints to be sealed. The amount used is determined by measuring the volume of the joint and taking into account the material’s specific gravity.

Application Method of Petroleum-resistant Mastic Sealant

How should petroleum-resistant mastic sealant be applied?

The substrate surface must be clean and free from any grease, dust, or contaminants. If there is any contamination, the surface should be cleaned using water jetting or sandblasting. The liquid component (resin) of the anti-solvent mastic should be heated directly over a flame until it becomes molten and fluid. The mastic melting process should be carried out in a double-walled boiler with a maximum temperature of 160°C, while continuously stirring. Care should be taken to heat the resin to a point where it does not burn or produce smoke. Once the mastic becomes fluid, reduce the heat slightly, add the powder component, and mix thoroughly using an electric mixer to create a homogeneous blend. The prepared solution should be poured into the joint in a manner that ensures uniform filling without creating air bubbles. The mastic should be at least 130°C to 140°C during pouring. It is important to apply petroleum-resistant mastic at temperatures above 5°C and in dry, wind-free conditions. If formwork is required for mastic pouring, the form materials should be chosen to withstand the mastic’s heat during application and maintain their shape. It is recommended to protect the edges of the joint with masking tape to prevent contamination, but this tape should be removed immediately after the mastic is applied.

Safety of Petroleum-resistant Mastic Sealant

What safety precautions should be taken when using petroleum-resistant mastic sealant?

- This material is not flammable.

- In case of contact with skin or eyes, wash immediately with fresh water.

- If swallowed, seek medical attention immediately.

- Avoid inducing vomiting in the victim.

Storage of Petroleum-resistant Mastic Sealant

What are the storage conditions for petroleum-resistant mastic sealant?

- Shelf life: One year in its original packaging

- Storage conditions: Keep away from freezing, heat, and prolonged direct sunlight

- Optimal storage temperature: 10°C to 30°C

Packaging of Petroleum-resistant Mastic Sealant

How is petroleum-resistant mastic sealant packaged?

- 20 kg kit

- Component A: 17.5 kg

- Component B: 2.5 kg

Reviews

There are no reviews yet.