Screw Wedge

The use of a standard screw wedge is another essential task in tiling. Every day, we witness innovations in modern and creative technologies, tools, and equipment such as the screw wedge, which are designed and produced to enhance comfort, increase productivity, and improve quality in various construction, industrial, and other fields. The screw wedge, by improving and changing construction methods, has made significant contributions in these areas. Moreover, modern equipment and tools for tiling are constantly advancing and developing.

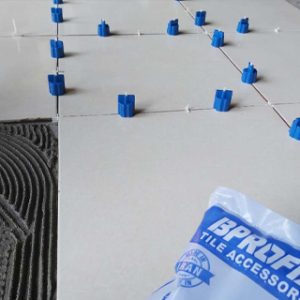

In tiling, besides the color and design of the tiles and ensuring they are set properly, what is particularly important is the leveling and alignment of the tiles in relation to each other, as well as maintaining precise gaps between the tiles. This is what brings beauty and improved quality to tiling. One of the modern tools developed for leveling tiles is the screw wedge, which consists of two parts: the clip and the screw wedge. It is made from durable plastic. The clip and screw wedge function similarly to a screw and nut, where they interlock to align the tiles properly.

The screw wedge is used for leveling tiles, and in addition to ensuring proper alignment and gap spacing, it also brings other benefits such as faster execution and the elimination of the need for tools like levels or hammers. In traditional methods of tile installation, hammers and levels are used to level the tiles, which requires positioning each tile individually, making the process much more time-consuming than using a screw wedge.

Usage Method: The screw wedge consists of two parts: the clip and the screw wedge. The clip is made up of two perpendicular parts. The horizontal part of the clip is flat and placed under the tiles, while the vertical part, the screw wedge, is shaped like a spiral rod. The screw wedge cap is circular and has a similar structure to a nut at its top, allowing it to screw onto the clip.

When placing two tiles next to each other, the number of screw wedges needed is determined by the size of the tiles. The clip is placed at the junction of the two tiles, and when the wedge is tightened onto the spiral rod, it aligns the tiles with each other.

Applications

- The screw wedge improves comfort, productivity, and quality in tiling.

- It ensures precise leveling of tiles.

- It eliminates irregularities between tiles.

Consumption Rate: The quantity of screw wedges required for a tiling project depends on the tile size and the area to be covered. Smaller tiles require fewer screw wedges per side, while larger tiles need more.

For small tiles (e.g., 30×30 cm):

- One screw wedge per side is sufficient. Ensure the wedge is placed in the center of each side. For increased accuracy, you can also place one screw wedge at the junction where the tiles meet.

For tiles measuring 40×40 or 50×50 cm:

- Two screw wedges per side are recommended. They should be placed 10 cm from the edges of the tile, with one wedge in the center and another at the junction.

For tiles ranging from 60×60 to 80×80 cm:

- Three screw wedges per side are needed, placed 10 cm from each edge and one in the center.

For tiles larger than 80×80 cm:

- For each 20-25 cm of a side’s length, one screw wedge should be used.

Important Notes

- The screw wedge is designed for tiles with a minimum thickness of 8 mm. It is not suitable for use with flooring like parquet, and for tiles thinner than 8 mm, a flat spacer should be used.

- Allow enough time for the mortar or adhesive to set before breaking the clip. If the mortar is still wet, the tiles may shift, disrupting their alignment.

- The screw wedge is reusable, while the clip is disposable. If you’re installing tiles in stages, buy fewer screw wedges than clips to save costs.

Packaging

- Standard screw wedge (50 pairs) in 50 bags.

- Standard screw wedge clips (100 pieces) in 25 bags.

- Screw wedges (50 pieces) in 50 bags.

Reviews

There are no reviews yet.