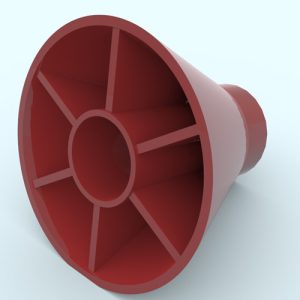

Heavy Conical Sleeve

Heavy Formwork Conic

Heavy Plastic Conical Sleeve

The heavy conical sleeve is a highly durable and efficient product made from compressed plastic, capable of withstanding significant lateral loads. It is commonly used in modern concrete formwork systems, including large panel systems, tunnel form systems, and Shams formwork systems, in lengths of 15, 20, 25, 30, 35, and 40 centimeters. This component is used to determine the distance between two formwork panels and allow the passage of bolts through them.

Due to its material and thickness, the heavy conical sleeve can handle high loads and withstand impacts and pressure exerted by formwork during assembly or movement by crane. The two-cone design allows the sleeve to be easily removed after concrete pouring by applying pressure from the smaller end of the cone to push it out from the larger end.

With the increasing use of industrial concrete formwork systems, especially those designed for larger-scale construction projects, heavy concrete formwork systems, like tunnel forms, are essential. These large molds require bolts, nuts, washers, and other anchoring components to secure lateral pressures. However, because of the large size and weight of the molds, bolts with a diameter of 22 millimeters are used to hold the lateral forces. In this case, components like double-cone sleeves or plastic waterproofing middle bolts cannot be used. The heavy formwork, coupled with the risk of impact, necessitates a protective cover that provides sufficient strength and durability. The heavy conical sleeve is the ideal solution for passing a 22-millimeter bolt in heavy-duty formwork systems.

Overall, this component plays an essential role in securing formwork against the pressure of the concrete. It is specifically designed to allow for easy removal after the process is complete by using a two-cone plastic sleeve. The use of bolts and pressure-holding equipment is crucial in the concrete formwork process.

This component serves as a protective cover, specifically designed to shield against mechanical damage, impact, wear, and environmental conditions. The design of the part helps distribute forces and pressures evenly across its surface, ultimately preventing stress concentration.

How to Use the Heavy Plastic Conical Sleeve

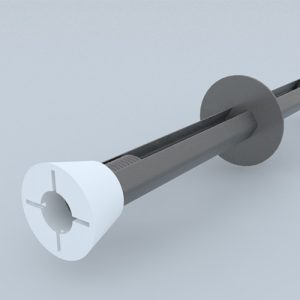

- First, the rebar structure is woven, and the necessary spacers to ensure concrete cover between the rebar and formwork are placed.

- Next, one side of the wall formwork is closed, and at the designated locations for bolt passage, a 22-millimeter bolt is inserted from outside the formwork and through the rebar network.

- The heavy plastic conical sleeve is then placed over the bolt, and the other side of the formwork is closed.

- Using struts, nuts, and washers, the formwork is completed and stabilized.

- After the concrete is poured and the formwork is removed, the bolt is removed, and once the concrete has gained proper strength, the heavy conical sleeve is removed by applying pressure from the smaller end of the cone, and the resulting hole is filled with an appropriate mortar.

Consumption Rate of the Heavy Plastic Conical Sleeve

On average, 2 heavy conical sleeves are required for each square meter of wall. However, the total amount of heavy conical sleeves needed corresponds to the number of bolts used in the concrete wall.

Important Notes about the Heavy Plastic Conical Sleeve

- It is recommended to lubricate the surface of the component with form oil before pouring the concrete to facilitate easier removal of the heavy conical sleeve from the concrete.

- To remove the sleeve, pressure and impact should be applied from the smaller diameter side.

- If the resulting hole needs to be waterproofed, it is advised to use a mixture of grout and waterproof adhesive to fill the hole.

Reviews

There are no reviews yet.