Waterproofing Mid Bolt

The Waterproofing Mid Bolt is the most affordable and cost-effective type of mid bolt used for sealing the passage of bolts in concrete. It is designed and manufactured from plastic material, consisting of five parts that are assembled and used together. Compared to other mid bolts, such as cast iron or spring mid bolts, the plastic waterproofing mid bolt reduces costs by up to 70% and is highly cost-effective for contractors.

One of the key advantages of using the plastic waterproofing mid bolt over other metallic or cast iron mid bolts is the use of a standard one-piece bolt. This allows for use in other projects, unlike cast iron or metallic mid bolts, which require smaller bolts or special bolts with different threads, limiting their use in other projects. As mentioned, the plastic waterproofing mid bolt provides significant economic benefits for contractors.

For pouring concrete in various concrete walls, such as shear walls, reservoir walls, swimming pools, water transfer channels, tunnels, dams, etc., proper formwork must be used, considering the thickness and diameter of the wall and its intended use. In nearly 95% of concrete wall formwork systems, measures must be taken to secure the formwork against the hydrostatic pressures of concrete during pouring, preventing the formwork from opening and collapsing. One of the key elements for securing against lateral concrete pressure is using bolts, nuts, washers, and formwork braces.

In hydraulic structures where concrete waterproofing is a critical concern, the hole left by the bolt after formwork removal and bolt extraction becomes a structural weakness that needs to be sealed. Filling the hole with cement mortar, especially in thick walls, is challenging and can lead to water leakage if not done correctly.

The best method for waterproofing the bolt passage in concrete is to take measures before pouring the concrete when placing the bolt in the structure. The plastic waterproofing mid bolt allows for easy extension by adding a longer grooved plastic tube (the middle part of the assembly), which is a limitation with cast iron or metallic mid bolts and incurs higher costs. The main components of the plastic waterproofing mid bolt are made of PVC (polyvinyl chloride), which does not negatively affect the concrete. Additionally, the parts of the mid bolt that remain in the concrete (tube and connector) have grooves to ensure a better bond with the concrete.

Overall, this product is a specialized component for concrete pouring with different variants for various applications, most commonly used for waterproofing concrete walls or sections. It is also crucial in concrete formwork systems for creating resistance to water penetration and ensuring the structural integrity of concrete structures. With unique features such as high water resistance, durability, and easy installation, it helps improve the quality and lifespan of the structures.

Main Components of the Plastic Waterproofing Mid Bolt

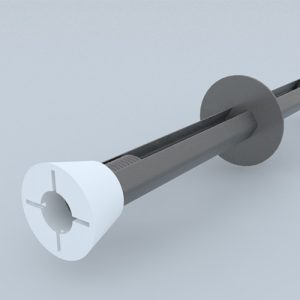

- Connector: The connector is the intermediate piece between the conical part of the mid bolt and the grooved plastic tube. It remains embedded in the concrete after installation, and rubber stoppers (U or T type) are placed inside the connector and the tube to secure them in place.

- Conical Part: This is the final part used in waterproofing the bolt passage. After the concrete curing and formwork removal, the conical part is removed from both ends of the mid bolt so that the rubber stoppers can be inserted into the connector.

- Rubber Stopper (U Type): This part is used for sealing the middle section of the bolt passage and is made from soft, durable PVC. It is placed inside the connector during waterproofing.

- Rubber Stopper (T Type): This part seals both ends of the bolt passage and is inserted into the connector after formwork removal. It ensures complete sealing of the holes created by the mid bolt.

- Grooved PVC Tube: The grooved PVC tube serves as the intermediary piece in the assembly of the mid bolt. It helps in adjusting the length of the waterproofing mid bolt and enhances the bond between the tube and the concrete.

How to Use the Plastic Waterproofing Mid Bolt

- Pre-Assembly: The connector, conical part, and grooved PVC tube are assembled before the concrete pouring process.

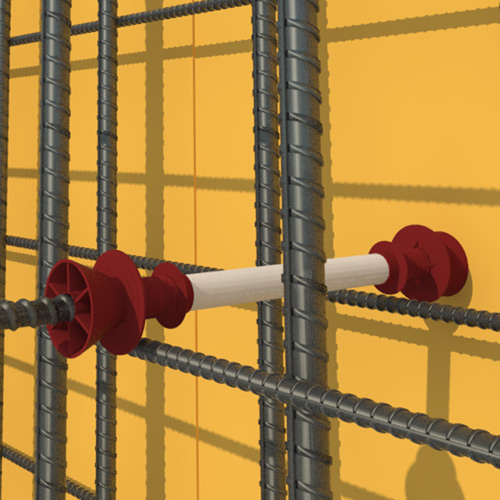

- Formwork Installation: After setting up the reinforcement mesh and placing spacers, one side of the formwork is assembled. A bolt of the appropriate length (based on wall thickness and the type of braces) is inserted from the outside of the formwork.

- Installing the Mid Bolt: The plastic waterproofing mid bolt is placed as a casing around the bolt, then the other side of the formwork is installed, ensuring the bolt exits evenly from both sides of the formwork.

- Securing the Formwork: After confirming that the formwork is stable and can withstand the hydrostatic pressure, the concrete pouring process can begin.

- Post-Pour Removal: Once the concrete has set, the formwork is removed, and the conical part of the mid bolt is extracted using pliers. A conical hole is left in the concrete, providing access to the connector.

- Waterproofing: First, a U-type rubber stopper is inserted into the hole. Then, T-type rubber stoppers are inserted from both ends to complete the sealing. Finally, grout mixed with waterproofing adhesive is used to fill the conical cavity to ensure complete waterproofing.

Consumption Rate of Plastic Waterproofing Mid Bolt: The consumption of mid bolts is determined by the number of bolts needed to withstand the lateral concrete pressures. Typically, 2 mid bolts per square meter are required.

Important Notes

- The plastic waterproofing mid bolt is only used as a casing for passing bolts.

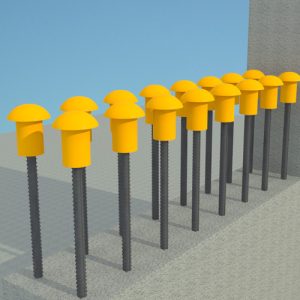

- Even if the bolt passage does not require sealing, the conical part must still be removed from the concrete to avoid structural weakness.

- The plastic mid bolt prevents the concrete slurry from leaking out through the formwork holes.

- The T-type and U-type rubber stoppers are essential for proper sealing, and their removal or reduction is not allowed.

- The plastic waterproofing mid bolt is designed for bolts with diameters of 16 or 18 mm and is not suitable for larger diameters.

Assembly Process of the Plastic Waterproofing Mid Bolt:

- Reinforcement mesh is laid out, and one side of the formwork is assembled according to the project design.

- The appropriate bolt is inserted, and the plastic waterproofing mid bolt is placed as a casing around it.

- After assembling both sides of the formwork and securing it, concrete pouring is completed.

- After curing, the formwork is removed, and the cone part of the mid bolt is extracted to access the connector.

- The rubber stoppers are inserted into the connector, and the hole is filled with a waterproofing grout.

With these procedures followed accurately, 100% waterproofing is achieved through the plastic waterproofing mid bolt.

Reviews

There are no reviews yet.